Unwanted reflections are a daily problem for spectacle wearers. Common complaints include reflections from the front and back surfaces of the lens, optical dispersions, and ghost images. Light rays from multiple sources are always hitting the lens from all angles on both the front and back surface. There are multiple light sources in both our indoor and outdoor environments from artificial and natural sources, all of which may cause unwanted reflections on our lenses.

Ophthalmic lenses have a loss of transparency caused by the interaction of the light with their surfaces. The result is the appearance of ghost images. Ghost images appear in standard lenses, decreasing wearer’s visual acuity and causing sparkles. This happens when the light is reflected from the front of the lens to the back, and back to the front. The wearer sees two objects instead of one.

The aim of anti-reflective coatings has always been to increase the transparency of our lenses to achieve a more natural look and get rid of those ghost reflections whilst improving vision clarity. Satin Klear UV, is the most advanced and transparent AR coating that we offer and is a first-class anti-reflective coating with 99.8% transmission rate*.

Satin Klear UV lenses enhance the performance of prescription lenses by reducing glare for clearer vision, whilst improving the cosmetic appeal of eyewear. The coating provides a reflection value of only 0.2% per side as well as superior aesthetics with colour stability; even at high angle of incidence.

Satin Klear lenses are nearly invisible thanks to the improved transparency of the coating and significantly reduced reflections on both the front and back surface of the lens. Satin Klear is the only coating within the Satin family that reduces light reflections from any angle, resulting in less distracting glare and better lens aesthetics. Satin Klear is the perfect choice for brightly coloured designer frames, or rimless models.

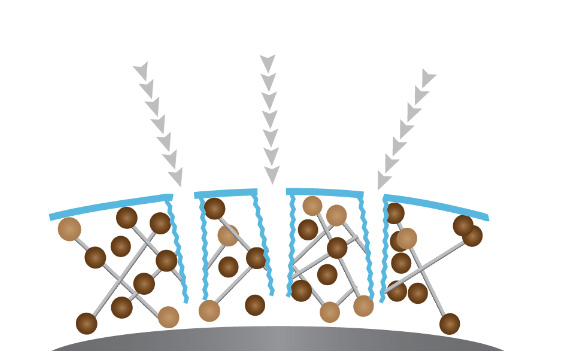

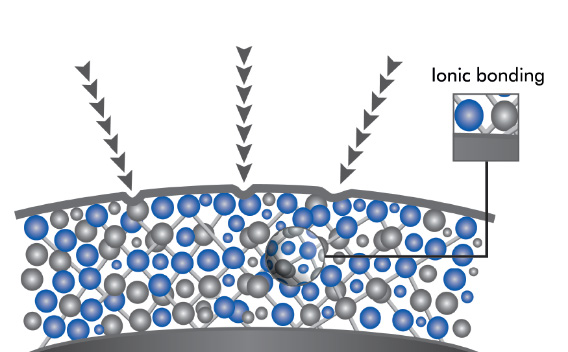

As well as the enhanced coating durability and UV protection from both lens surfaces, Satin Klear provides all of the benefits associated with the wider Satin coatings range. The Enhanced Scratch Guard Technology of Satin coatings has a good adhesive property, which makes the coating hard and provides excellent scratch resistance when applied to the surface of the lens. The formula is flexible and created using ionic bonding to help prevent cracking and peeling of the coating.

Most modern lenses are made from either plastic or polycarbonate. These materials provide many benefits over more traditional glass lenses, but the material itself is softer, and therefore more susceptible to scratches. The application of a high quality Satin coating will help protect the lenses from scratches through every day wear and tear. The coating is also very easy to clean, ensuring that keeping the lenses in their best possible condition is simple and straightforward.

Ordinary lens

Satin Plus

ES Guard technology also has an index matching property that makes the application of Satin coatings unique to each lens index, and also provides tint stability for all materials. The coating process is carried out at a controlled temperature in a state of the art facility to achieve maximum scratch resistance properties on the lens.

The anti-reflection properties of Satin coatings also improve the aesthetics of the lenses, as well as the visual clarity and comfort for the wearer. Anti reflective coatings are especially recommended for use with polycarbonate and high index lenses, as the material properties can cause more reflections than regular plastic lenses.

Water droplets will quickly slide off the lens surface producing the Lotus effect thanks to the LQ Technology of Satin coated lenses. With the help of LQ Technology, the contact angle increases to more than 110 degrees, ensuring excellent hydrophobic properties.

SD (smudge & dust) Guard Technology is a protective layer applied to Satin coated lenses that guards against dust particles and oil. This layer makes the lens oleophobic, preventing oil and dirt from penetrating into the lens material, thus making the lens smudge resistant. It also reduces the accumulation of frictional static charge by neutralising the lens surface, in turn reducing dust accumulation making the lenses almost dust free.