It doesn’t matter if we are out during the day or night; we are always affected by intrusive reflections and glare. Reflections from the surface of uncoated and hard-coated ophthalmic lenses also add to the problem for spectacle wearers.

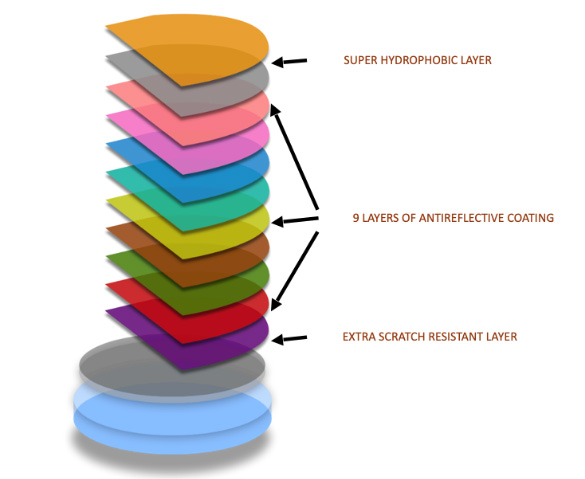

The Satin Aktiv coating is made up of multiple microscopic chemical layers that alternate between high and low indexes of refraction. Each of these layers affects different wavelengths of light and reduces their reflections. The more of these layers that there are in the coating, the more reflections are neutralised. Satin Aktiv reduces a significant amount of reflections compared with other HMC coatings. Despite this, the 9 layer coating stack only comprises around 0.02% of the overall lens thickness of the lens. This coating is applied to both the front and back surface of the lens.

Satin Aktiv reflects back and filters blue-violet light*, and a portion of the infra red light spectrum. The coating offers incredible clarity and sharpness for wearers and can be applied to our Rx designs.

*Protection against UV and blue-violet light filtering. (Blue-violet light is between 400 and 455nm as stated by ISO TR 20772:2018).

The anti-reflective properties of Satin Aktiv makes this coating a great choice for wearers who spend a lot of time driving, particularly during darkness, as the coating perfectly balances light transmission with glare reduction and contrast. Wearers will experience reduced eye strain from the headlights of oncoming traffic, and will be less likely to have to squint because of light glare. Wearers will see the benefits of this coating during their daily activities outside the car too, with enhanced contrast and clarity, as well as improved lens aesthetics with a reduced colour bloom.

Lower contrast at night without coating

Higher contrast at night with coating

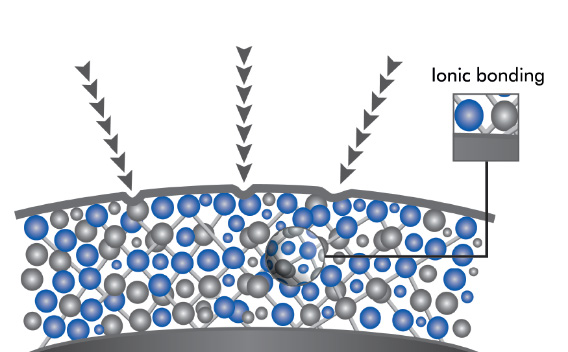

As well as the enhanced coating durability and UV protection from both lens surfaces, Satin Aktiv provides all of the superb benefits associated with the Satin coatings range. The Enhanced Scratch Guard Technology of Satin coatings has a good adhesive property, which makes the coating hard and provides unparalleled scratch resistance when applied to the surface of the lens. The formula is flexible and created using ionic bonding to help prevent cracking and peeling of the coating.

Most modern lenses are made from either plastic or polycarbonate. These materials provide many benefits over more traditional glass lenses, but the material itself is softer and therefore more susceptible to scratches. The application of a high quality Satin coating will help protect the lenses from scratches through every day wear and tear. The coating is also very easy to clean, ensuring that keeping the lenses in their best possible condition is simple and straightforward.

Ordinary lens

Satin Plus

ES Guard technology also has an index matching property that makes the application of Satin coatings unique to each lens index, and also provides tint stability for all materials. The coating process is carried out at a controlled temperature in a state of the art facility to achieve maximum scratch resistance properties on the lens.

The anti-reflection properties of Satin coatings improve the aesthetics of the lenses, as well as the visual clarity and comfort for the wearer. Anti reflective coatings are especially recommended for use with polycarbonate and high index lenses, as the material properties can cause more reflections than regular plastic lenses.

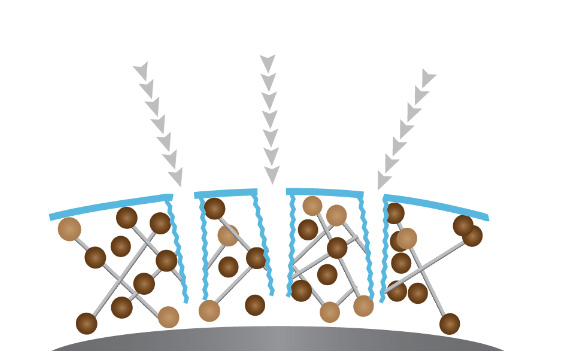

Water droplets will quickly slide off the lens surface producing the Lotus effect thanks to the LQ Technology of Satin Plus. With the help of LQ Technology, the contact angle increases to more than 110 degrees, ensuring excellent hydrophobic properties.

SD (smudge & dust) Guard Technology is a protective layer applied to Satin Plus lenses that guards against dust particles and oil. This layer makes the lens oleophobic, preventing oil and dirt from penetrating into the lens material, thus making the lens smudge resistant. It also reduces the accumulation of frictional static charge by neutralising the lens surface, in turn reducing dust accumulation making the lenses almost dust free.